Chemical engineering majors get crude

The oil industry spends about $30 billion per year in capital investments to expand the flow of crude oil. One source of crude oil can be found in the tar-like substance known as bitumen or oil sands. Bitumen can be separated, treated and blended to produce synthetic crude oil (SCO) which can then be upgraded to light gas oil, diesel and other hydrocarbon mixtures used in energy production.

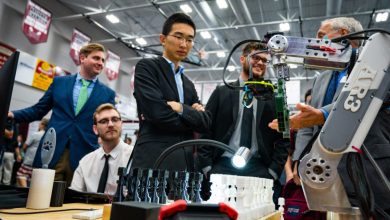

Athela Frandsen, chemical engineering major, and her senior design team Samantha McCusky and Dennis Hogan are working on ways to help enhance the bitumen extraction and processing procedure based on past successes in the industry. “It’s a lot more cost-effective to turn bitumen into synthetic crude oil on-site, than to transport the bitumen for off-site processing,” says Athela.

Athela and fellow chemical engineering majors created a 3D printed version of their on-site bitumen processing plant to showcase at the Northrop Grumman Science and Engineering Design Showcase where they won best in show for chemistry. Athela hopes that their design and processing insights will help improve the industry. “With the development of more domestic hydrocarbon resources, we have the potential to make our country and our neighbors more economically and politically independent from other oil-producing nations,” she says.

Beyond the cost-savings associated with enhanced bitumen processing plants, there are other benefits. “If we turn bitumen into synthetic crude oil that floats and pump that instead of the raw bitumen that sinks, it’s much easier to cleanup if a spill does occur,” she says.