Students Test Technologies for Hypersonic Jet

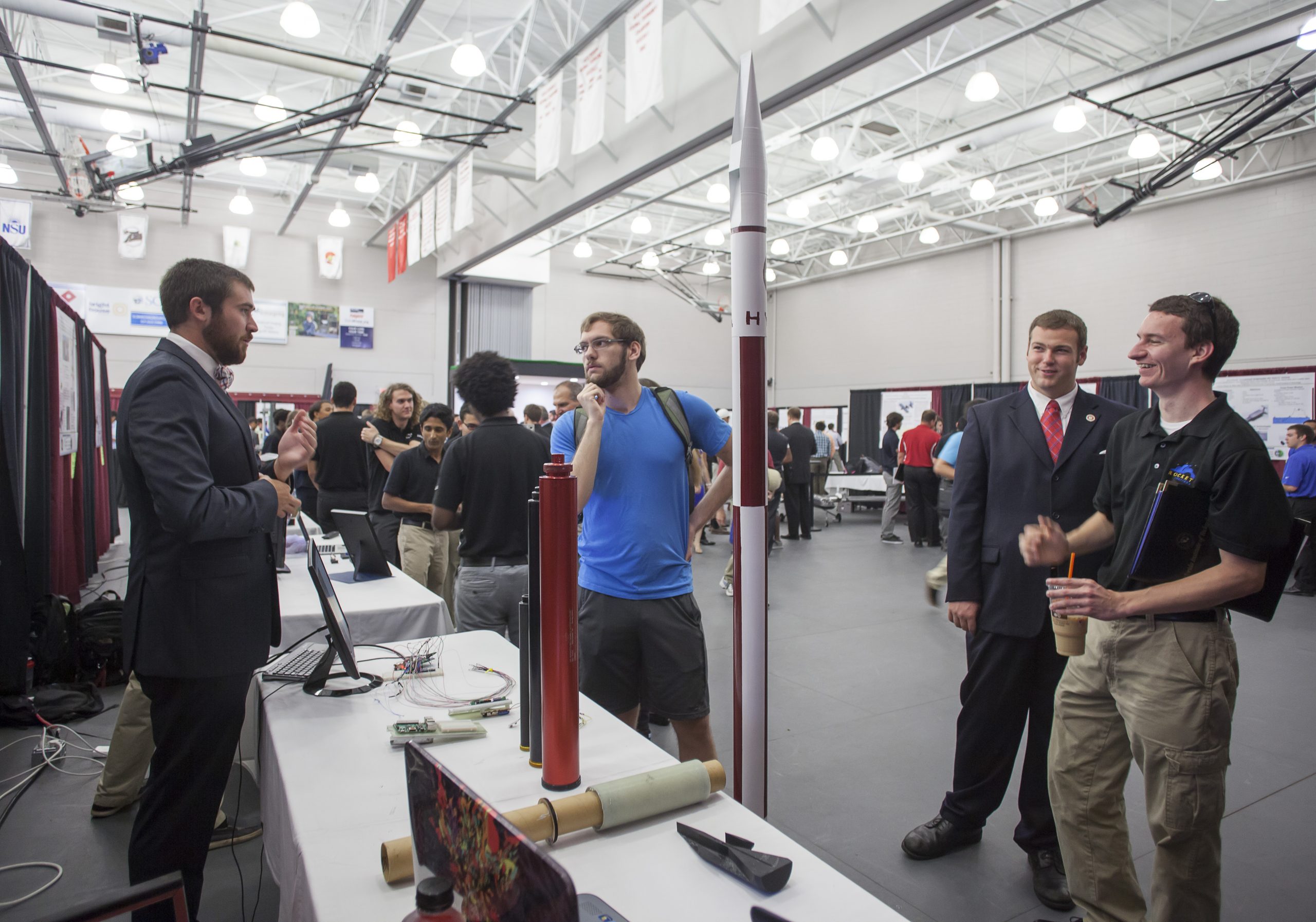

Nine aerospace engineering students are using a rocket as a testbed for hypersonic jet technologies, such as scramjet engines.

The project, called HYDRA, (HYpersonic Dynamics Rocket Assembly), is designed to fly supersonically and gather data on the static pressures in the inlet of the nosecone, the cone shaped nose of a hypersonic jet.

Aerospace engineering student Kathryn Disher said the team originally planned on designing the transition stage of a single-stage-to-orbit vehicle. The team was approached by a professor about the hypersonic jet project, HYDRA, while in the research and concept phase, and the two projects required similar background knowledge to pursue. They looked at HYDRA and thought about its feasibility as well as its impact on the industry and decided to go with it.

Aerospace engineering student Kathryn Disher said the team originally planned on designing the transition stage of a single-stage-to-orbit vehicle. The team was approached by a professor about the hypersonic jet project, HYDRA, while in the research and concept phase, and the two projects required similar background knowledge to pursue. They looked at HYDRA and thought about its feasibility as well as its impact on the industry and decided to go with it.

The nosecone is the combination of a normal nosecone with a scale model of a scramjet inlet; for symmetrical purposes, they used two inlets in the actual nosecone. Along the inner wall of the inlet(s), there have pressure sensors, which connect to a Raspberry Pi microcomputer, storing the readings on an SD card.

Disher said, “This year, the project is proof of concept, so we’re going to fly it transonically as a test of the system, comparing results to expected results we obtained from running simulations in ANSYS.”

The team’s goal is to provide a method of testing scale-models supersonically instead of hypersonically. The system will be reusable, and it will provide a means of testing that is cheaper, easier to schedule and less dangerous to use than current methods.

Currently, the methods that exist for testing hypersonic technologies are expensive, hard to book, and/or dangerous. For example, there’s a method that involves taking the fully-operational experimental aircraft and flying it.

“Granted,” Disher said, “this occurs very high in the atmosphere and away from populated areas, but there are still people involved in the testing, not to mention the cost of building, fueling, and flying it. If anything went wrong, there would be lives lost and a lot of funding gone down with the aircraft.

“Things are structured a specific way and controlled in lectures and labs and everything goes as it’s supposed to. However, in student design, it is not like that and that is a good thing,” said Disher.

Disher said the team learned how to use certain programs better and gained more experience working with different technologies, like 3D printers and laser-cutters. The team also gained real-world experience working on HYDRA. They have all taken different parts of the project, like research and development, paper writing, purchasing, fabrication and testing.

“This has given us real problems so that we could come up with real solutions; we’ve been able to do what we came here for!” Disher said. “We actually got to feel what it’s like to be engineers, to sit down after seeing a problem and try to fix it, learning along the way, and I thought that that was pretty great.”

Disher advises students not to panic when things are not going as planned.

Disher advises students not to panic when things are not going as planned.

“You’re going to hate everything for a little while because it’s like you’re fighting a losing battle, but as long as you don’t give up and you keep working you’ll reach your end goal,” Disher said. “Don’t cut corners, don’t throw everything away, don’t tell your teammates that you think they’re terrible…work together, and don’t give up.”