NASA JPL Student Design Team Makes Mini Rovers for Mars 2020 Mission

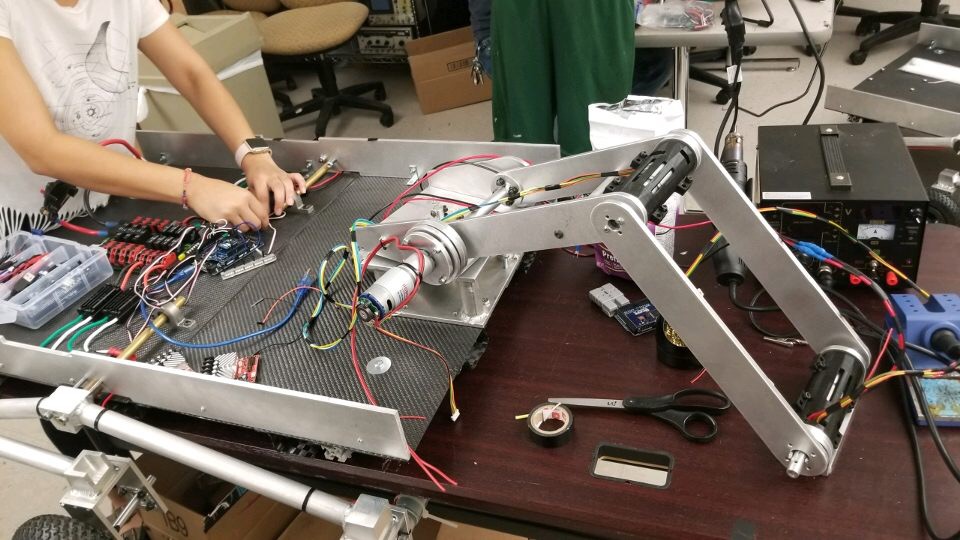

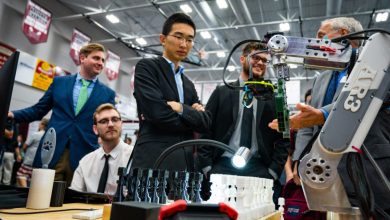

Twenty-one Florida Tech students are days away from revealing two mini rovers they’ve spent hundreds of hours creating at the 2018 Northrop Grumman Student Design Showcase.

The students are part of this year’s NASA JPL Senior Design team working on mini rovers for the Mars 2020 mission.

JPL stands for “Jet Propulsion Laboratory” — NASA’s leading center for robotic exploration of the solar system.

“We were basically just given a problem statement by NASA — assist the Mars 2020 mission or the Europa mission,” said McKenzie Clark, the team’s manufacturing lead.

“After weighing both options, we chose to pursue a project on Mars rather than Europa (a moon of Jupiter),” she said.

Florida Tech’s NASA JPL team decided the best way to assist the Mars 2020 mission would be to design a synergistic system of miniature rovers able to work independent of each other as well as perform joint mission tasks.

“These mini rovers can perform the same tasks as a larger rover can, but there are two of them,” Clark said. “So if one fails, the mission isn’t a complete failure — and they can still carry out the basic tasks.”

The idea behind having two smaller rovers that can communicate, rather than just one larger rover, is to increase the system lifespan, survivability, amount of ground covered and quantity of data gathered.

According to Clark, mini rovers have been made by the European Space Agency (ESA) but have never been sent to Mars.

“…which is why we wanted to elaborate on the concept,” she said.

The project is a prototype, but the team hopes the concepts will be utilized on actual rovers.

Clark said the hardest part of the process has been making things easy to manufacture.

“Something will look pretty on the CAD model, but when you come to actually put it together and make it, it’s very difficult,” she said.

Clark, who is responsible for making sure everything from the CAD model makes it into the actual model, said the biggest success has been watching all the pieces come together.

“It’s really great to see your idea and your imagination come to life in the physical object,” she said.