Panthers Shoot for the Moon

Part of the Exploration Ground Systems crew, 25-plus Florida Tech alumni are playing integral roles in virtually every aspect of NASA’s Artemis campaign for the moon.

Written in collaboration with NASA Public Affairs

“We are going!” is the battle cry for NASA’s Artemis campaign to fly a human-rated spacecraft farther than any other in the history of space exploration. The historic mission seeks to land the first woman and person of color on the moon, establish the first long-term human-robotic presence on and around the moon and, eventually, send the first astronauts to Mars.

Kennedy Space Center’s (KSC) Exploration Ground Systems (EGS) could be considered the bow that will launch Artemis’ arrow in the form of Artemis I, the first uncrewed integrated flight test of NASA’s Deep Space Exploration Systems: the Space Launch System rocket (SLS) and Orion spacecraft.

EGS develops and operates the equipment and facilities required to connect a spacecraft and rocket, transport the launch vehicle to the launch pad and launch it into space. Historically, the work centered around a single kind of launch vehicle—such as Saturn V or space shuttle. Today, however, EGS is preparing the infrastructure for several kinds of spacecraft and rockets, including the SLS and Orion spacecraft.

Among EGS’ ranks are more than 25 Florida Tech alumni who lead, program, implement and will launch the Artemis I maiden mission around the moon. From engineers and analysts to managers, business people and computing experts, these Panthers have dedicated their careers—some, for decades—to prepare this first-of-its-kind infrastructure and capabilities.

Meet some of EGS’ Florida Tech alumni and see what they’re working on as they count down to liftoff.

Left row, from left: Dion Ramiscal ’94, Curtis Byrd ’84 M.S., Josiah Ruelas ’20, Keith Braun ’98, Melanie Murphy, Raymond Francois ’20;

Right row, from left: Skip Williams ’80, Jose Amador ’91, ’94 M.S., ’01 Ph.D., Rebecca (Bec) Mazzone ’04, ’09 M.S., Kristin Kendall ’95, ’96, Sunita Ramnarinesingh ’09, ’12 M.S., Michael Thompson ’17

Photo: NASA

Mobile Launcher 1 & 2

The 400-foot ground structures that are used for assembling, processing and launching the Artemis program missions. Mobile Launcher 1 (ML1) will launch the first three missions; Mobile Launcher 2 (ML2) will incorporate structural modifications and lessons learned from ML1.

Fun Fact: ML1 weighs about 11.3 million pounds!

Alumni Involved

John Moss ’12 M.S., Deputy Project Manager, ML2

Keith Braun ’98, Ground Integration Engineer, ML1 and ML2

Jason McCaw-Binns ’07, ’09 M.S., Lead Ground Integration Engineer, ML1

Lauren-Ann Graham ’20, Mobile Launcher Ground Integration Engineer, KLXS III contractor

I absolutely love Florida Tech and currently am a mechanical engineering graduate student. I dream of becoming an astronaut, so Florida Tech—with its location, history and curriculum—was, and is, the obvious choice to prepare for a shot at the Artemis astronaut corps.”

LAUREN-ANN GRAHAM ’20

Space Launch System (SLS)

The world’s most powerful rocket and the only one capable of sending Orion, astronauts and cargo to the moon on a single mission.

Fun Fact: While SLS has greater power than its predecessor, Apollo’s Saturn V, it is over 40 feet shorter!

Alumni Involved

Dion Ramiscal ’94, SLS Core Stage Operations Project Engineer

Launch Pad 39B

Originally designed for the Saturn V launch vehicle, EGS recently implemented modifications to upgrade it to a “clean pad” able to launch a variety of rockets, including the SLS.

Fun Fact: The pad’s Ignition Overpressure and Sound Suppression System dumps 400,000 gallons of water—enough to fill 27 average-size pools—on the mobile launcher and inside the flame trench in less than 30 seconds!

Alumni Involved

Sunita Ramnarinesingh ’09, ’12 M.S., Project Manager, Launch Pad 39B

Kristin Kendall ’95, ’96, Project Manager, Launch Pad 39B

Josiah Ruelas ’20, Launch Site Integration Engineer/Payloads

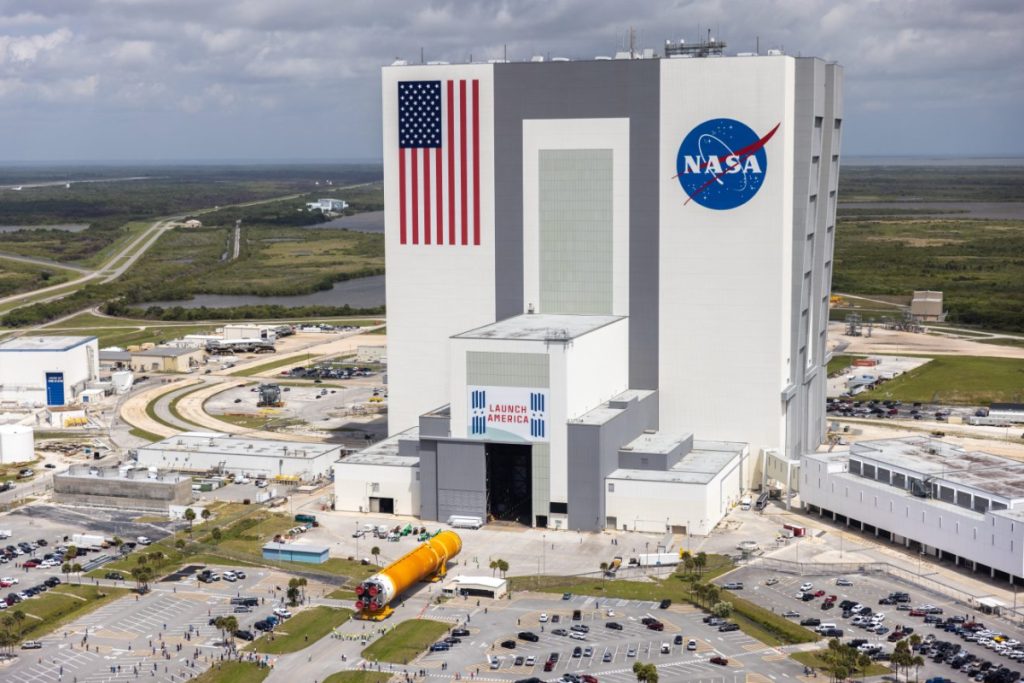

Vehicle Assembly Building (VAB)

Photo: NASA

The central hub of NASA’s multiuser spaceport. From shuttles to external fuel tanks to solid rocket boosters, the VAB serves as the final assembly point for a variety of rockets, spacecraft and their parts—often, simultaneously.

Fun Fact: By area, the VAB is one of the largest buildings in the world—525 feet tall, 518 feet wide and covering 8 acres. Also, it is home to the largest American flag—209 feet by 110 feet—painted on the side of the building.

Alumni Involved

Martyn Eastwood ’80, Project Manager, KLXS III Contractor

Multi-Payload Processing Facility

Photo: NASA

KSC’s “gas station” for fueling rockets and payloads with hazardous commodities.

Alumni Involved

Skip Williams ’80, Mission Integration Operations Manager

Williams and his team are responsible for preparing, fueling and processing hazardous commodities for space-bound vehicles—including the Orion spacecraft, which they have fueled and readied for its Artemis I mission around the moon. Once it has splashed down, the team will process Orion again to remove any residual hazardous materials.

That’s the heart of integrated engineering—it often has no end point but leads to the next process step. … There’s zero error tolerance when working with hazardous materials.”

SKIP WILLIAMS ’80

EGS Leadership

Outside of the Artemis program, EGS’ mission is to transform KSC from a government-only launch complex to a spaceport capable of managing a variety of both government and commercial spacecraft and rockets.

Alumni Involved

Sasha Sims ’07 M.S., Chief of Staff

As chief of staff, Sasha Sims ’07 M.S. facilitates collaboration among the leadership team, aiming to balance competing priorities for the Artemis mission.

We place high emphasis on employee development, learning and mentoring to ensure we have the right skills in the right place to accomplish our goals. … EGS is an incredible team of dedicated people who dream big and work immensely hard on behalf of the nation.”

SASHA SIMS ’07 M.S.

John Kunkle ’02, ’05 M.S., Chief, Ground Integration

With oversight of both Artemis I and Artemis II-IV launch campaigns within his direct work scope, John Kunkle ’02, ’05 M.S., and his team translate mission requirements into the necessary KSC ground support equipment and infrastructure for an array of KSC operations and launches.

No two days are ever the same, which is what makes this position both fascinating and complex. … Every day presents a unique challenge in terms of solving technical issues as well as partnering solutions and building a team across the agency and industry.”

JOHN KUNKLE ’02, ’05 M.S.

Darrell Foster ’91, Ground Systems Integration Manager

Darrell Foster ’91 is a Brevard County native and Florida Tech legacy who was hired by NASA before he even graduated. Today, he leads the design, development and testing of KSC ground systems and infrastructure, overseeing several cross-functional project teams that consist of hundreds of people who enable critical launch processing requirements for the SLS, Orion and other NASA spacecraft.

I was hired by NASA two weeks before graduation and literally took off my Florida Tech student ID badge and clipped on a NASA credential. … It doesn’t get any better than that in professional life.”

DARRELL FOSTER ’91

José J. Amador ’91, ’94 M.S., ’01 Ph.D., Project Manager, Ground Control Subsystem (KGCS); Co-Lead, Integrated Product Team, KGCS/GSE Software

Marcia Groh-Hammond ’83 M.S., Logistics Lead

Jill Clark ’03, NASA Programmatic Integration Lead

Michael Thompson ’17, NASA Operations Project Engineer

Nadia Shokrani ’20 M.S., Cross Program Schedule Analyst

Florida Tech was collaboration-focused, and that prepared me for working on a large program like Artemis. A launch requires thousands of people working in unison and, working in planning, I see how all these people come together to realize something extraordinary.”

NADIA SHOKRANI ’20 M.S.

Curtis Byrd ’84 M.S., Budget Analyst

John “Paul” Douglas ’97, Cross Program Integration Engineer, KLXS III Contractor

Frederick Stotz ’12 M.S., Test Project Engineer, TOSC Contractor

Melanie Murphy, Finance Intern

Launch Control Center (LCC)

Photo: NASA

Houses software enabling communication between launch team operators in Firing Room 1 (located in the LCC), team members in the VAB, mobile launcher and Launch Pad 39B, the astronauts aboard Orion, controllers at the Air Force Eastern Range and other NASA control centers.

Alumni Involved

Sharif Abdel-Magid ’10, ’15 M.S., NASA Test Director

Like a conductor to an orchestra, NASA test directors such as Sharif Abdel-Magid ’10, ’15 M.S., are masters at ensuring that process protocols are executed according to exact procedure and timing.

Being at the critical mass of a launch is stressful but electrifying beyond description. Florida Tech was challenging, and I’m glad it was because it prepared me to work successfully in the greatest pressure-packed environment on Earth.”

SHARIF ABDEL-MAGID ’10, ’15 M.S.

Rebecca Mazzone ’04, ’09 M.S., Command and Control Modeling and Simulation Team Training

Randal Goodmon ’83, Facility Element Operations Manager

Landing and Recovery

Photo: NASA

Underway Recovery Test-7 (pictured) is one in a series of tests that EGS, in conjunction with the U.S. Navy, is conducting to validate procedures and hardware that will be used to recover Orion.

Fun Fact: The USS John P. Murtha is the ship tasked with recovering Orion from the Pacific Ocean, about 60 miles off the coast of San Diego.

Alumni Involved

Christine St. Germain ’07, ’08 M.S., NASA Test Director

The Artemis I launch is going to be incredible, yet our Orion recovery team will rest easy only after the spacecraft safely splashes down in the Pacific and is loaded onto the recovery ship. … That is when we’ll fully exhale.”

CHRISTINE ST. GERMAIN ’07, ’08 M.S.

Raymond Francois ’20, Orion Operations Engineer, TOSC Contractor

This piece was featured in the fall 2022 edition of Florida Tech Magazine.