How is 21st-Century Manufacturing Changing?

By Michael Grieves

The key to any resurgence of manufacturing in America will not be in working longer or working harder. The key will be in working smarter. America will never compete with low wage countries in doing traditional manufacturing and assembly. However, the advances in digital technologies mean that we can transform traditional, labor-intensive manufacturing into 21st century manufacturing that reduces costs dramatically.

Product Lifecycle Management (PLM) and its concept, the Digital Twin, is all about working smarter. The premise behind PLM is to create a Digital Twin of the products we wish to manufacture and manage them throughout the products’ entire lifecycle—from idea to retirement. The ideal of Digital Twin is the ability to design, test, manufacturing, operate and support the product in a virtual environment using inexpensive digital “bits.”

Only when we demonstrate that the product can be manufactured efficiently and will perform with the reliability and quality our customers expect do we actually move around expensive physical atoms in new manufacturing methods such as 3-D printing. This Digital Twin method reduces both the costs and time to design and manufacture products. It also increases the quality and reliability that improves customer satisfaction. We make the product “virtually perfect” before we make a physical product that delights customers.

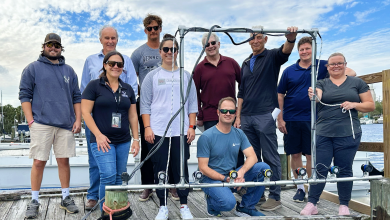

Florida Tech’s new Center for Advanced Manufacturing and Innovative Design (CAMID) has been created to advance these 21st Century design and manufacturing concepts. CAMID is creating an ecosystem of large manufacturers, their small to medium manufacturing (SMMs) suppliers, our students, and our faculty. In CAMID, this ecosystem will come together, both physically in our new facility in Palm Bay and virtually over the internet.

CAMID’s purpose will be to engage in projects that not only advance the research and development of 21st Century manufacturing, but to educate and train both the workforce of the future, our students, and the existing workforce who need these new skills.

CAMID has the opportunity to lead the way, not only locally, but regionally and even nationally in 21st-century manufacturing. PLM and its associated Digital Twin is the digital-based approach to design and manufacture products in America that are superior and globally competitive.

Michael Grieves is the executive director of CAMID and a research professor in the colleges of Business and Engineering. He is the author of the seminal books on PLM. His latest is Virtually Perfect: Driving Innovative and Lean Products through Product Lifecycle Management.