Center for Advanced Manufacturing and Innovative Design

Florida Tech will use a $1.4 million grant from the U.S. Economic Development Administration to launch the Center for Advanced Manufacturing and Innovative Design.

This 100,000-square-foot facility in the former Intersil building in Palm Bay will advance the capabilities of U.S. companies in next-generation manufacturing methods while ensuring students are exposed to technology and ideas that will influence the global manufacturing marketplace for years to come.

Known as CAMID, the facility at Florida Tech’s Research and Development Center on Palm Bay Road will enhance the digital product development and operations of manufacturers as well as their supply chains. CAMID will also assist corporate clients and students.

Commerce Secretary Penny Pritzker recognized the importance of this endeavor, saying in announcing the grant that the facility “will help ensure that American manufacturing continues to thrive.”

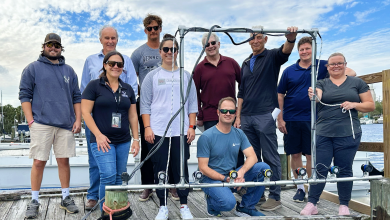

“CAMID will bring together industry, students and professors in a facility that will provide product development and manufacturing hands-on assistance, education and training, and research on 21st-century technologies that will make and keep manufacturers globally competitive,” said Michael Grieves, CAMID director and long-time executive in technical fields with an emphasis on start-ups.

The facility will offer the latest digital modeling, simulation and visualization technologies as well as computer-driven manufacturing equipment. It will operate under the “hoteling” model that allows companies to use the facility as needed. When the work is done, companies will return to their own operations.

“With CAMID, we are creating a system of services, equipment and expertise that exemplifies Florida Tech’s credo of high tech with a human touch,” said president and CEO Anthony J. Catanese.

Dwayne McCay, Florida Tech’s executive vice president and COO, said CAMID will surely become a critical asset for both the business community and the university.

“It will support industrial partners with training and advanced manufacturing techniques. It will educate students and even displaced workers on advanced manufacturing, process improvement and other areas. And it will allow us to perform groundbreaking research on new best practices for advanced and cyber-enabled manufacturing.”