DBA Student Leads Business Incubator Developing Technology to Combat COVID-19

Since the outbreak of the novel coronavirus, people and businesses around the world have rallied to develop new and innovative ways to manufacture vital health care resources like ventilators, face masks, gloves and more.

Breweries are making hand sanitizer. Vehicle manufacturers are building ventilators. And in southern Maryland, technology think tank TechPort is developing a sanitization appliance that will enable medical professionals to reuse personal protective equipment (PPE).

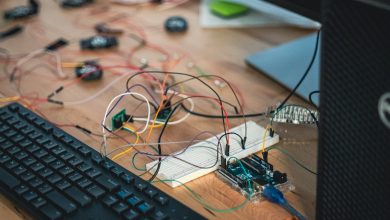

Led by Florida Tech Doctor of Business Administration (DBA) student Tommy Luginbill, TechPort is an unmanned aircraft system (UAS) business incubator operated by the University of Maryland College Park that is located in an airport hangar and is typically focused on drone and airplane technology.

After the virus began seeping into the United States, one of TechPort’s interns approached Luginbill, asking to use the facility’s resources to 3D-print a face mask for local first responders using a model he’d found online. Of course, Luginbill agreed.

On March 19, TechPort 3D-printed its first face mask and shared a photo of it with the public. The response was overwhelming.

“It got all sorts of attention, and this is before everybody was wearing them,” Luginbill says. “And so, the group of us started to figure out, ‘Well, maybe we can just keep making these, and what’s stopping us from making other things?’”

They created a channel on Slack, an online communication platform, demonstrating how to 3D-print the same face mask. Within days, hundreds of engineers had joined the channel, sharing ideas for how to tweak the original mask design, building ventilators out of breast pumps and developing new designs for 3D-printing and/or sewing other vital equipment, like face shields, hospital gowns, gloves and more.

The group had created thousands of units and was growing at such a rapid pace that Luginbill, along with Matt Hayes, the nonprofit’s founder/technical lead and a guest speaker for Florida Tech’s Southern Maryland education center, quickly recognized the opportunity and necessity to start an official nonprofit organization.

On March 28, Southern Maryland (SoMd) Loves You was born.

“We’ve donated to homes, hospitals, nursing homes. People are very grateful to say the least,” Luginbill says. “And on the flip side of that, we’re obviously grateful for the people that are actually going in every day to do the work.”

Despite the impressive volume of equipment SoMd Loves You—and the rest of the world—has produced, Hayes recognized that eventually, it will run out. So, he set out to develop a way to sanitize and reuse such materials.

“We figured out pretty quickly the best way to do it was with heat,” Luginbill says. “We actually got a local partner, and they were so moved by what we were doing, we had a steel fabricator that literally designed a 5,000-pound steel oven within 72 hours.”

The group then transported the PPE sanitization device to a local hospital, where it underwent testing for several weeks, and on April 20, submitted the design to the U.S. Food & Drug Administration (FDA) for certification.

“There’s so many applications for the sanitation unit beyond just COVID-19. You can think of influenza, SARS, Ebola. And so, we’ve had people from all over the world start contacting us,” he says. “Obviously, we want FDA approval, but there are other agencies that can and will purchase the sanitation unit regardless of what happens.”

Aside from mitigating equipment shortages and saving money for health care organizations, Luginbill is excited by the sanitation unit’s potential impact on the environment through the major reduction of biowaste.

And while he foresees TechPort continuing its previous work with UAS companies once the country gets back to “normal,” Luginbill plans to continue pursuing development in the medical field, perhaps even merging the two industries by focusing on creating drones for things like blood and organ transplants.

“I think that the world has woken up to the idea that medicine and health care are more important than maybe we were taking it,” he says. “And I think that technology, no matter what the industry is, is going transcend over into the medical field.”