Exploring the Biofuel Potential of Corn Stalks

When we fill up our gas tanks, most pumps have a sticker informing us that the fuel “contains less than 10% ethanol.” This biofuel is produced primarily from corn. In harvesting corn for this use, or for food, producers are left with tons of corn stalks comprised of leaves and stems, with the stems consisting of cortex and pith (which may be better known as the white tissue around a peeled orange).

Though they often end up in our trashcans, these ingredients may in fact provide the next generation of sustainable biofuel.

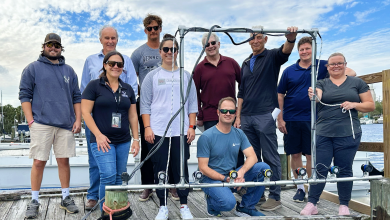

Florida Tech was recently awarded a four-year, $943,029 grant from the U.S. Department of Agriculture, “Development and Optimization of Mild Hydrothermal Preprocessing for High Ash Biomass into Pelletized Biorefinery Feedstocks.” While the ultimate goal is to turn the corn stalks into a fine powder that can then be processed into low-ash energy pellets, this grant will explore the pretreatment of those stalks as they need to be prepared before being sent to a biofuel processing plant.

The first part of the research will look at the feasibility of cleaning the stalks. Florida Tech is collaborating with the Idaho National Lab (INL) and its preprocessing technique called air classification. This method separates the soil from the stalks so the stalks can ultimately be used for pellets. Florida Tech will take the stalks that could not be cleaned at INL and subject them to hydrothermal treatments, which is done using water heated to between 482-705 degrees Fahrenheit and pressures of 4–22 megapascals, or up to nearly 4,000 pounds per square inch. The corn stalk biomass is degraded into small components in water, which will reduce the ash contents and impurities of the stalk.

Energy pellets are a rising sustainable energy source. Cleaner burning than gas or coal, pellets have also been found to be a more energy efficient, cost-saving energy source. While there has been some controversy with the use of forest-harvested wood to create pellets, biomass pellets would utilize farm waste to provide this alternative energy source.

“Currently, they’re not doing anything with the stalks, and it is a huge liability because the farmers need to clean the stalks then they would usually burn them,” project lead and Florida Tech chemical engineering assistant professor Toufiq Reza said. “So instead of burning it on-field, can we use it for high-value energy production?”

This area of research has on Reza’s radar for some time. Over the last year, Reza and Ph.D. students Tamid Islam, Nepu Saha and Kyle McGaugy, have been chemically treating corn stalks and making small pellets out of them. Early results indicate the treatments they are using can make the pellets burn similarly to wood pellets or even coal. While wood pellets need a binder keep the contents together, the biomass pellets from the corn stalks have what Reza calls a “natural binding ability,” eliminating the need for cohesive additives and allowing for a cleaner burn.

The goal of the preliminary work was to pinpoint the optimal conditions to produce these pellets amid various factors, such as the temperature, pressure and whether water needs to be added to the mix. Reza and his team are now looking to build a small reactor next year furthering the pellet research.

This project is only one part of a broader sustainability puzzle, but it is a significant one for the researchers involved. For Reza, it is a continuation of an overall push to move biofuel forward and create state-of-the-art technologies.

“It’s a good time to be part of this work,” he said. “I’m glad to see federal funding agencies are paying more attention to these negative value feedstocks, which can create liabilities for farmers and communities, and are allowing us to study how to best upcycle them to biofuel or chemicals that we can use.”

###